Aug 22,2024

By: BPC

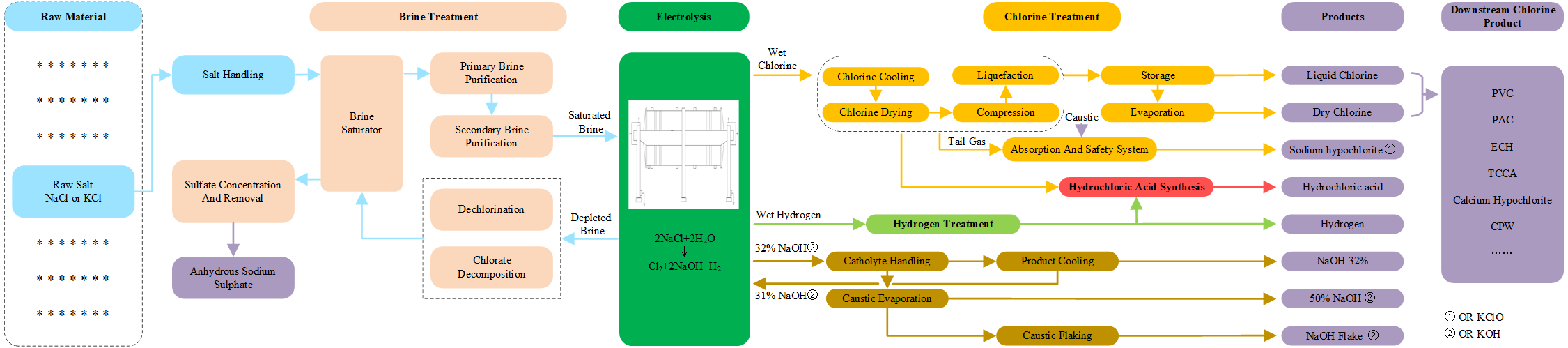

The chlor-alkali plant is an industrial facility that produces chlorine (Cl₂) and sodium hydroxide (NaOH), commonly known as caustic soda, through the electrolysis of sodium chloride (NaCl) solution, commonly referred to as brine. This process is fundamental in the chemical industry, providing essential chemicals for various applications.

Key Components and Processes:

1.Brine Preparation: Sodium chloride is dissolved in water to create a concentrated brine solution. The brine must be purified to remove impurities that can interfere with the electrolysis process.

2.Electrolysis Cell: The purified brine is fed into an electrolytic cell, where an electric current is passed through it. There are three main types of electrolytic cells used in the chlor-alkali process:

Mercury Cell: Uses a mercury cathode to produce sodium amalgam, which is then reacted with water to produce sodium hydroxide and hydrogen gas. This method is being phased out due to environmental concerns related to mercury.

Diaphragm Cell: Uses a porous diaphragm to separate the anode and cathode compartments. Chlorine gas is produced at the anode, and sodium hydroxide and hydrogen gas are produced at the cathode.

Membrane Cell: Uses a selective membrane to separate the anode and cathode compartments. This is the most modern and environmentally friendly method, producing high-purity sodium hydroxide.

3.Products:

Chlorine (Cl₂): Produced at the anode, chlorine is used in various applications, including the production of polyvinyl chloride (PVC), disinfectants, and solvents.

Sodium Hydroxide (NaOH): Produced at the cathode, sodium hydroxide is used in the manufacturing of paper, soap, and detergents, and in water treatment.

Hydrogen (H₂): Also produced at the cathode, hydrogen gas can be used as a fuel or in the production of ammonia for fertilizers.

Environmental and Safety Considerations:

Mercury Pollution: The mercury cell process poses significant environmental risks due to mercury emissions.

Energy Consumption: The electrolysis process is energy-intensive, so improving energy efficiency is a key focus for the industry.

Brine Purification: Proper purification and management of brine are necessary to prevent environmental contamination.

Gas Handling: Chlorine and hydrogen gases are hazardous and must be handled with care to prevent leaks and explosions.

Chlor-alkali plants are critical to the global chemical industry, providing essential chemicals for a wide range of industrial and consumer products. The industry is continually working to improve the efficiency and environmental sustainability of the production processes.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China