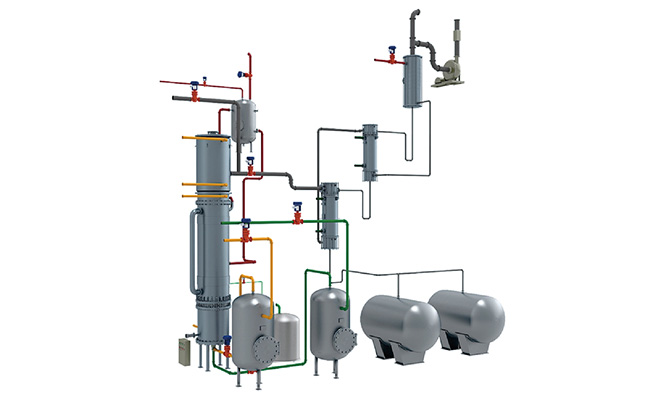

2 in 1 HCL synthesis unit mainly combines the synthesis section and cooling section together, and produce HCL gas through combustion of hydrogen and chlorine gas mixture under a proper ratio. Then the cooled HCL gas is delivered to processing lines (such as PVC, polycrystalline silicon and others in which the HCL gas is required) or flowing into absorption system to synthesize HCL acid.

Industry's top Team

Efficient Energy Saving

Acceptable Price

Fast Service Response

Committed to providing chlor-alkali customers with world-leading, one-stop, comprehensive chlor-alkali plant services

2 in 1 HCL synthesis unit mainly combines the synthesis section and cooling section together, and produce HCL gas through combustion of hydrogen and chlorine gas mixture under a proper ratio.

Then the cooled HCL gas is delivered to processing lines (such as PVC, polycrystalline silicon and others in which the HCL gas is required) or flowing into absorption system to synthesize HCL acid.

Meanwhile, we could adequately utilize the heat from the synthesis process to generate hot water or steam upon to customer"s requirement.

Equipped with digital control system (DCS), we could completely achieve an unattended operation on site.

We offer customization service. You just need to tell what you would like to customize in the below form then we will evaluate its feasibility and contact you in the earliest.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China