We adopt the "three-effect countercurrent falling film evaporation" process. The 32% NaOH solution sent from outside the boundary area is added to the III-effect falling film evaporator, where its concentration is increased from 32% to 36%. After being concentrated, the caustic soda solution is pressurized by the III-effect pump and then heated by the preheaters of the II-effect first and second stages before entering the II-effect falling film evaporator, where its concentration is further increased to 42%. The concentrated caustic soda solution is then pressurized by the II-effect caustic soda solution pump, heated by the preheaters of the I-effect first and second stages, and enters the I-effect falling film evaporator, where its concentration is raised to 50%. The caustic soda solution that has reached the desired concentration is pressurized by the I-effect caustic soda solution pump, cooled by the preheaters of the I-effect second stage and II-effect second stage as well as the caustic soda solution cooler, and then sent to the finished caustic soda tank outside the boundary area for storage.

Industry's top Team

Efficient Energy Saving

Acceptable Price

Fast Service Response

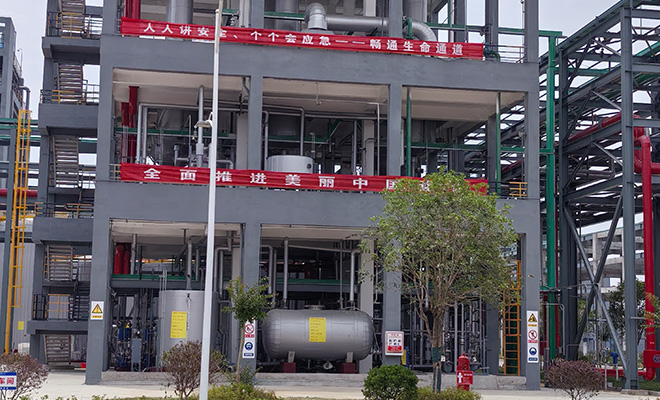

Committed to providing chlor-alkali customers with world-leading, one-stop, comprehensive chlor-alkali plant services

High efficiency: The countercurrent evaporation method improves evaporation efficiency and reduces energy consumption.

High level of automation: The application of the DCS system realizes real-time monitoring and automatic adjustment of process parameters, reducing manual intervention and improving production efficiency and product quality.

High safety: The DCS system has comprehensive safety protection functions, which can promptly detect and handle abnormal situations, ensuring production safety

We offer customization service. You just need to tell what you would like to customize in the below form then we will evaluate its feasibility and contact you in the earliest.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China