Based on BPC's leading position and rich experience in concentration, peeling, granulation and other fields. We can offer the complete processing system to produce calcium chloride which comes in the form of flakes, pellets / granules, powders and liquid solutions.BPC owns continuous fluidized bed spray granulation technology, an advanced technology at present in the calcium chloride industry. This technology has the features of large output, low energy consumption, high stability and good quality products. Rough granule and smooth granule production can be realized. Continuous fluidized bed spray granulation technology can realize 30 days trouble-free continuous running.

I. Synthesis Section

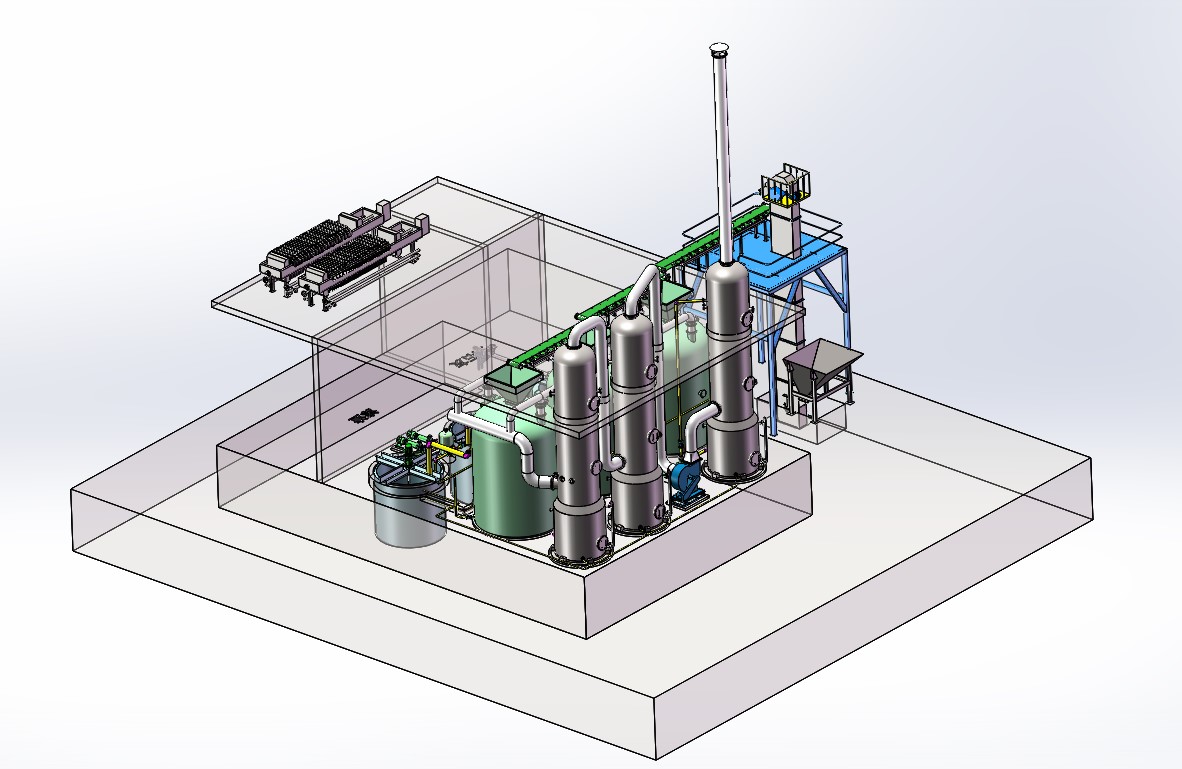

Calcium chloride is produced by hydrochloric acid and limestone reaction in the tank process, the reaction mixture is made of hydrated lime for PH adjustment and then pressed for filtration. The mother liquor obtained by pressing is precipitated and then sold directly or sent to the drying process to produce flake calcium chloride.We use calcium carbonate to neutralize the synthetic (or by-product) hydrochloric acid, and then uses calcium hydroxide emulsion to neutralize the acidic calcium chloride solution after the reaction. The reaction is complete, and neutralization thoroughly, and one-step reaction.

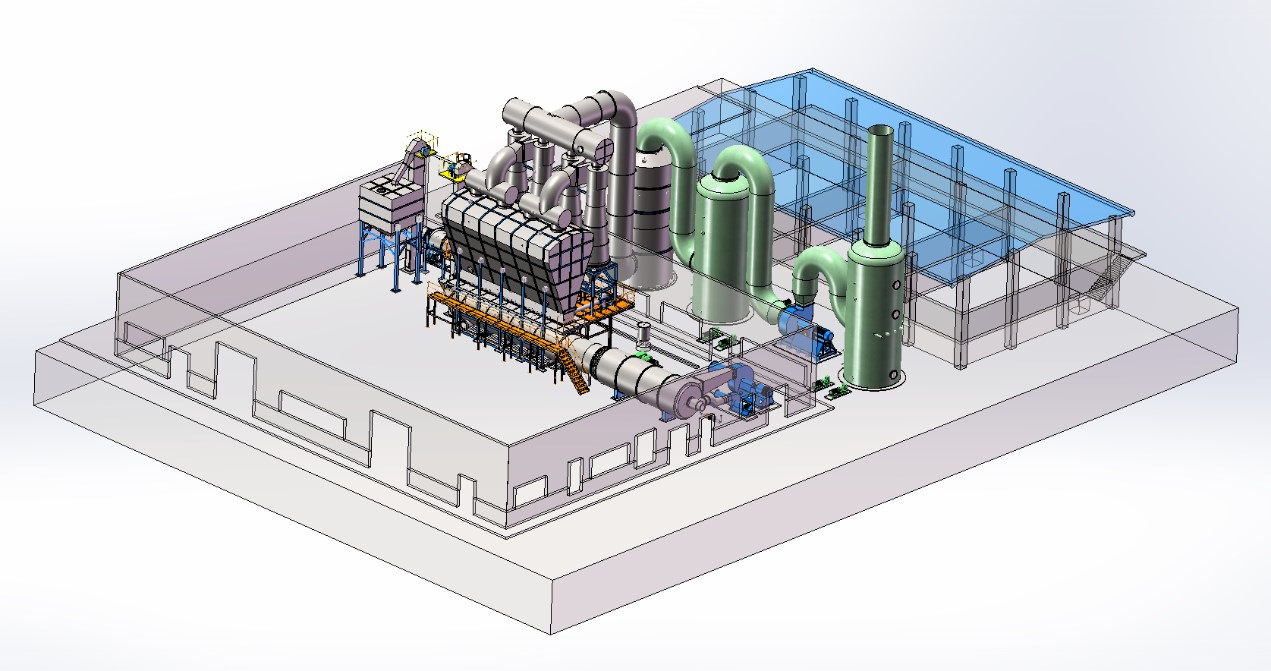

II. Granulation Section

Calcium chloride solution in atomized form is sprayed into a fluid bed granulator, where the droplets come into direct contact with the fluidized material layer. The droplets adhere to crystal nuclei, initiating the formation of a local infiltration layer. As water evaporates, smaller particles adhere to this layer, enlarging the crystal nuclei. This process is repeated continuously in the fluid bed, resulting in the gradual, overlapping, and uniform growth of particles. This granulation method yields particles with a uniform, compact structure, enhancing their strength.

Industry's top Team

Efficient Energy Saving

Acceptable Price

Fast Service Response

Committed to providing chlor-alkali customers with world-leading, one-stop, comprehensive chlor-alkali plant services

Integrated withspray, drying and granulation, making granulation realized in one step.

Parallel flow way of spray drying is adopted, so that heat sensitive materials can be easily operated.

Two stage drying methods: use spray drying and fluidized bed drying, so the water content can be very low.

The equipment is operated under closed negative pressure, so no dust generated.

We offer customization service. You just need to tell what you would like to customize in the below form then we will evaluate its feasibility and contact you in the earliest.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China