Dec 08,2024

By:

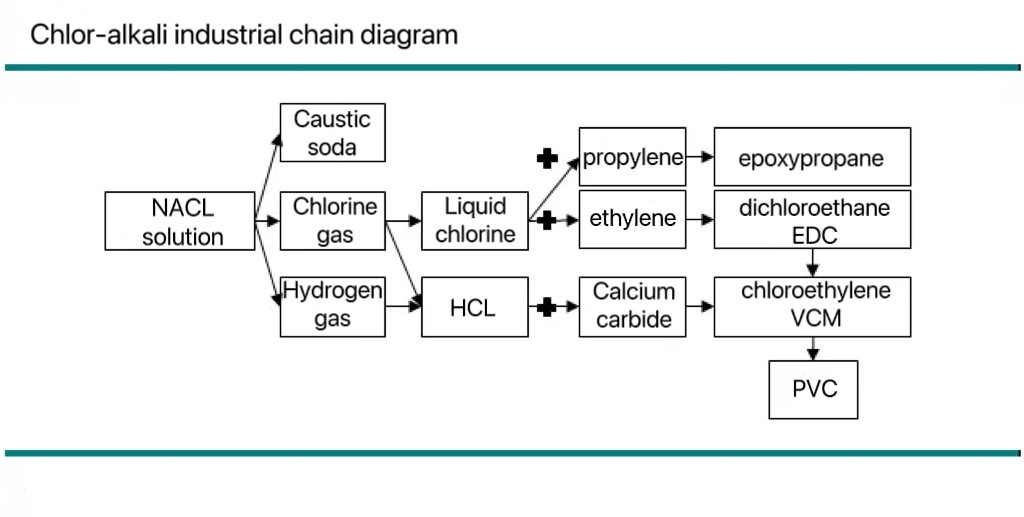

The chlor-alkali industry (caustic soda industry) is an important component of the chemical industry, which produces basic chemical raw materials such as caustic soda (NaOH), chlorine gas (Cl2), and hydrogen gas (H2) by electrolyzing saturated saline solution. As a fundamental chemical production technology, the chlor-alkali industry plays a pivotal role in the development of modern chemical industry worldwide. Caustic soda is the main product of this industry, while chlorine and hydrogen are considered by-products and play an irreplaceable role in various industrial fields.

At present, the chlor-alkali industry mainly adopts three different production processes, mercury method, membrane method, and ion membrane method. Although these three processes share the same chemical reaction principle and generate products through the reaction of 2NaCl+2H2O=2NaOH+Cl2+H2, they each have their own characteristics in practical operation. The mercury method uses mercury as an electrode to efficiently produce high-purity sodium hydroxide without chlorine. However, this method requires the use and emission of large amounts of mercury, which poses a significant pollution risk to the environment. With the strengthening of environmental regulations in the early 1970s, countries such as Japan, the United States, and Western Europe successively introduced laws to limit mercury emissions, promoting the widespread application of diaphragm laws. The diaphragm method separates chlorine gas and sodium hydroxide by adding a diaphragm in the electrolytic cell to reduce the mixing of impurities. Although it reduces the use and emission of mercury compared to the mercury method, it still has the problems of lower product purity and higher energy consumption. In order to address these issues, the ion exchange membrane method was industrialized in Japan and the United States in 1975. The ion membrane method combines the advantages of mercury method and membrane method, which not only has high product quality and low energy consumption, but also does not produce harmful substance emissions during the production process, becoming a widely used mainstream process in modern chlor-alkali industry.

Caustic soda, also known as sodium hydroxide, is a highly corrosive alkali. There are two forms of caustic soda: solid and liquid. Solid caustic soda is white and comes in flakes, granules, etc; Liquid caustic soda is a colorless and transparent liquid. Easy to dissolve in water to form an alkaline solution, also has deliquescence, absorbs carbon dioxide and undergoes deterioration.

Caustic soda is a basic chemical raw material, and downstream demand includes alumina, chemical industry, papermaking, printing and dyeing, etc. Caustic soda is widely used in the smelting process of aluminum in the metallurgical industry. By dissolving bauxite in a high-temperature caustic soda solution, high-purity alumina (Al2O3) can be extracted, and then further refined into pure aluminum metal through electrolysis. In the paper industry, caustic soda is used for pulp processing to remove non cellulose components and neutralize organic acids, in order to improve the quality and durability of paper. In the textile and printing and dyeing industries, caustic soda is used to remove oil, adhesives, and fine fibers from the surface of fabrics, softening them and making the dyeing process more uniform, thus improving the appearance and texture of finished products.

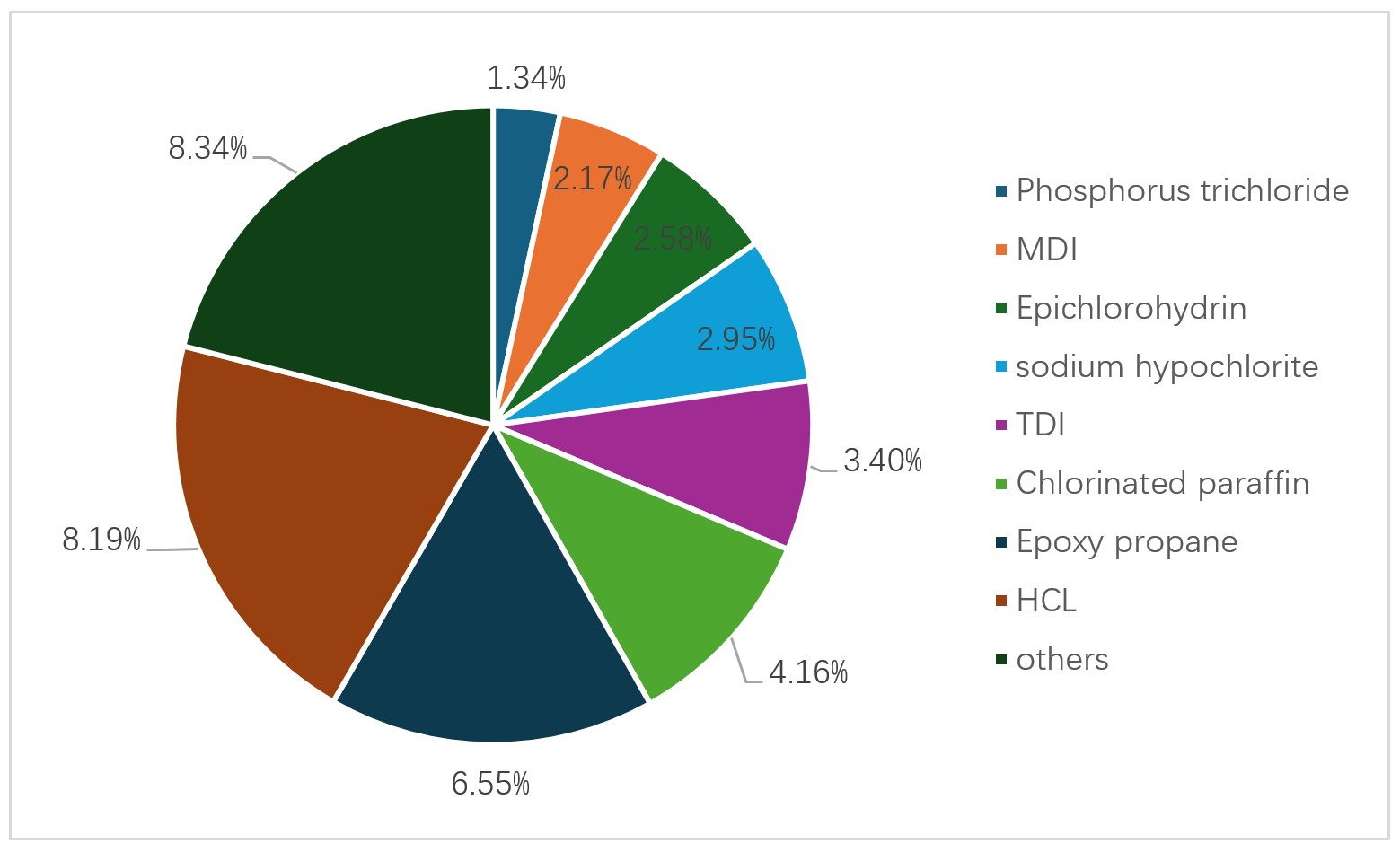

Figure: Liquid alkali (Liquid caustic soda) demand structure in 2023

Caustic soda, also known as sodium hydroxide, is a highly corrosive alkali. There are two forms of caustic soda: solid and liquid. Solid caustic soda is white and comes in flakes, granules, etc; Liquid caustic soda is a colorless and transparent liquid. Easy to dissolve in water to form an alkaline solution, also has deliquescence, absorbs carbon dioxide and undergoes deterioration.

Chlorine products can be divided into inorganic chlorine products and organic chlorine products. From the downstream structure of chlorine, it can be seen that inorganic chlorine products consume more chlorine in the total consumption of chlorine. At present, more than half of the total consumption of chlorine products in China is inorganic chlorine products, mainly inorganic chlorine, chloride and hydrochloric acid, which play an important role in the synthesis of pesticides, pharmaceuticals and other chlorinated polymer products. Hydrochloric acid is an important raw material in the chemical industry, used in various fields such as metal cleaning and acidifying oil wells; Organic chlorine products include polyvinyl chloride, epichlorohydrin, etc., which are important raw materials for polyvinyl chloride (PVC). As one of the world's five major general-purpose plastics, PVC is widely used in building materials, pipes, profiles, doors and windows, flooring, and other fields due to its excellent physical and chemical properties. Polyvinyl chloride is the largest organic chlorine product in China and the main product for regulating alkali chlorine balance.

Figure: Consumption Structure of Liquid Nitrogen in 2023

In the production process of chlor-alkali industry, the production of caustic soda, chlorine gas, and hydrogen gas is 1:0.886:0.025, which means that for every ton of caustic soda produced, 0.886 tons of chlorine will be generated simultaneously. Liquid chlorine can vaporize into gas under normal pressure, which can cause serious poisoning when inhaled into the human body. It has a strong irritant effect and corrosiveness, is flammable and explosive, and belongs to dangerous goods. Storage of more than 5 tons is classified as a major hazard source, with high transportation costs.

Therefore, how to consume chlorine gas has always been an unavoidable issue in the industry. Chlor-alkali enterprises generally determine the operating rate of chlor-alkali based on the downstream market demand for liquid chlorine, digest liquid chlorine on site, and sell caustic soda externally. Generally speaking, chlor-alkali plants in the northwest region of China adopt a chlorine fixed alkali mode, with PVC as the main product and caustic soda as a by-product. The chlor-alkali plants supporting the alumina industry in Shanghai and Shandong also adopt a model of using alkali to determine chlorine, with chlorine as a by-product.

When the demand for caustic soda in the market is high, chlor-alkali enterprises will increase their production of caustic soda. However, due to the co production of caustic soda and liquid chlorine, as the production of caustic soda increases, the production of liquid chlorine will also increase accordingly. If the market demand for liquid chlorine is relatively low at this time, enterprises will face the dilemma of ineffective digestion of liquid chlorine. To avoid inventory buildup and factory production disruptions, companies may have to sell liquid chlorine at extremely low prices, and in extreme cases, they may have to pay back shipping costs to ensure timely shipment. In this case, the losses caused by the sale of liquid chlorine will be compensated by the profits from caustic soda, that is, "using caustic soda to supplement chlorine".

When the market demand for liquid chlorine is strong, leading to an increase in its price, chlor-alkali companies often choose to increase production capacity to meet the growing demand for liquid chlorine supply. With the improvement of production, caustic soda as a co product will inevitably increase significantly. However, due to the lack of synchronous increase in market demand for caustic soda, or the market's delayed response to changes in demand, the demand elasticity of the caustic soda market is relatively low, making it difficult to quickly absorb the newly added supply. This supply-demand imbalance can lead to an excess of caustic soda, putting downward pressure on its price. In some extreme cases, companies may be forced to sell caustic soda at a price lower than cost in order to maintain the normal production and sales of liquid chlorine, and even engage in reverse payment to ensure that the production and sales of liquid chlorine are not affected, that is, "supplementing alkali with chlorine".

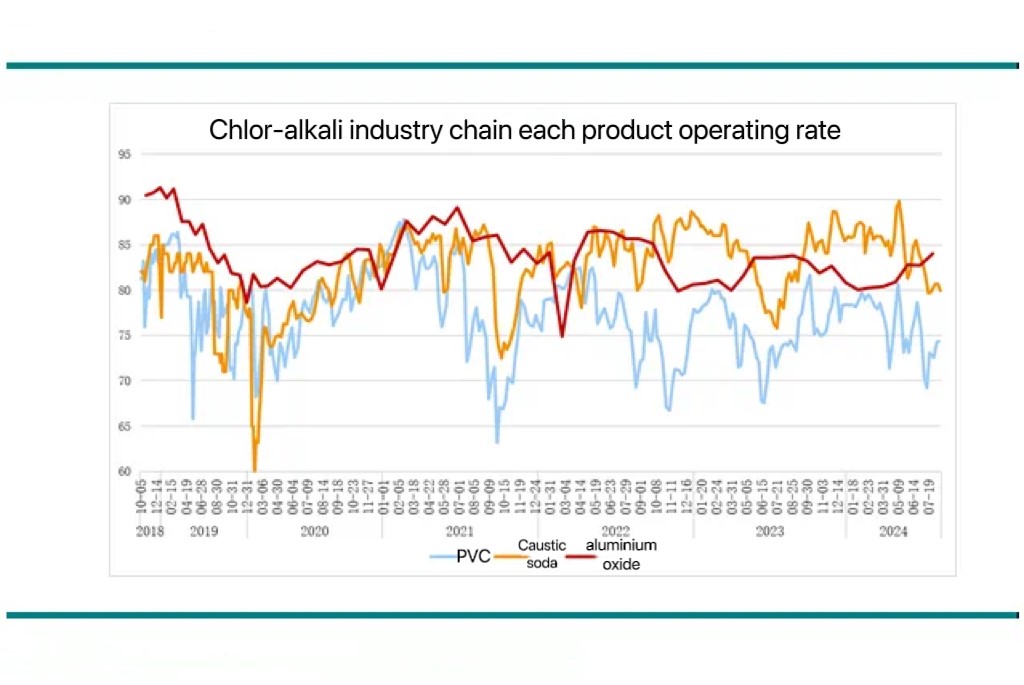

According to actual data, the operating rate of alumina is generally slightly ahead of that of caustic soda, while the operating rate of caustic soda and PVC is more consistent. The profit of the electrolysis unit is negatively correlated with the profit of PVC as a whole. The production of alumina requires a large amount of caustic soda, so when the operating rate of the alumina industry increases, the demand for caustic soda will also increase accordingly, promoting chlor-alkali enterprises to increase the production of caustic soda. Due to the fact that the alumina industry is one of the main downstream industries of caustic soda, the operating rate of alumina usually slightly precedes the operating rate of caustic soda. Therefore, the production adjustment of caustic soda is usually a response to changes in downstream demand and profits.

Meanwhile, the operating changes of caustic soda and PVC are often consistent. Liquid chlorine is an important raw material for producing PVC, and liquid chlorine and caustic soda are co produced. When enterprises increase the production of liquid chlorine to meet the demand for PVC, the production of caustic soda will also increase synchronously. When the demand for caustic soda increases, liquid chlorine is also produced synchronously, consuming excess through the production of PVC. Therefore, the production changes of PVC directly affect the overall operating rate of chlor-alkali enterprises, making the trend of operating rate changes of caustic soda and PVC tend to be consistent.

Figure: Operating rate of main products in the chlor-alkali industry chain

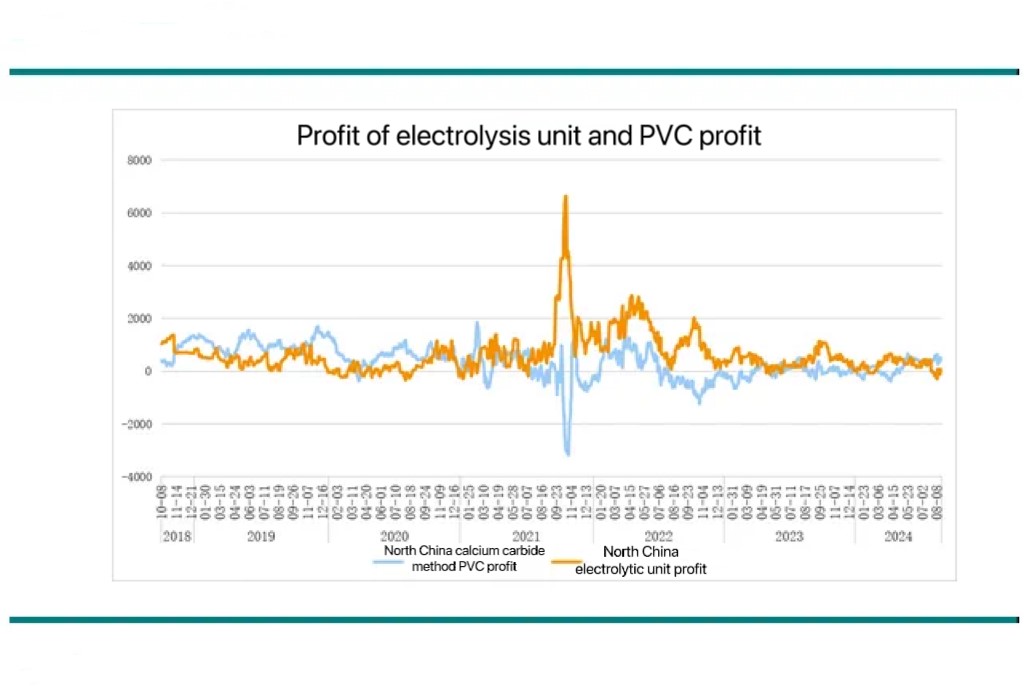

Regarding the negative correlation between the profits of electrolytic units and PVC, when the market demand for PVC is strong and prices rise, chlor-alkali enterprises will increase their production of liquid chlorine to meet the demand for PVC. In this case, due to the co production of liquid chlorine and caustic soda, the production of caustic soda will also increase. If the market demand for caustic soda cannot increase synchronously at this time, the excess supply of caustic soda will lower its market price, thereby reducing the profit of caustic soda and leading to a decrease in the overall profit of the electrolysis unit. This situation reflects the high profit period of PVC, which is often accompanied by a decrease in profits of electrolytic units, reflecting a negative correlation between the two.

Figure:Profit of electrolysis unit and PVC profit

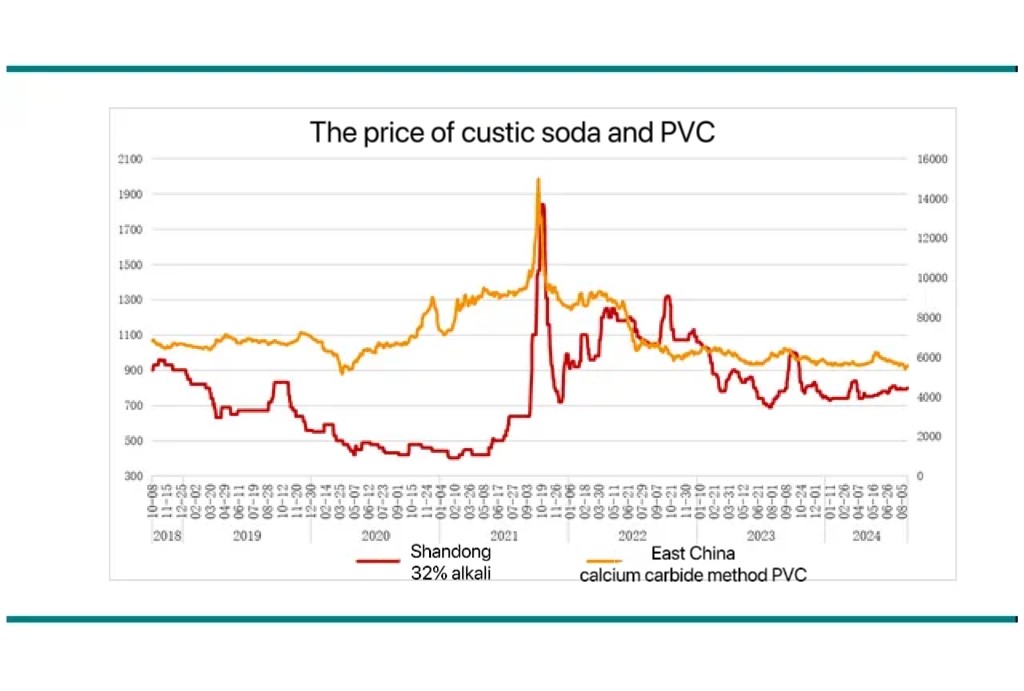

In terms of absolute price, there is no significant negative correlation between caustic soda prices and PVC prices.

Although caustic soda and PVC are co products, their downstream market demand is driven by different factors. Caustic soda is mainly used in various industries such as alumina production, papermaking, textiles, and chemical engineering. The demand of these industries is often closely related to infrastructure construction, manufacturing activities, and fluctuations in global trade during the economic cycle. PVC is mainly used in the production of plastic products such as building materials, pipes, doors, windows, and flooring, and its demand is more directly affected by the real estate market and infrastructure construction investment.

The impact of economic cycles on different industries often varies over time. The cyclical fluctuations in the construction industry (affecting PVC demand) may occur first in a certain period of time, while the manufacturing or chemical industry (affecting caustic soda demand) may exhibit different cyclical fluctuations in subsequent periods. This time difference results in relatively independent fluctuations in the prices of caustic soda and PVC at certain stages, rather than a simple negative correlation.

During the period of economic expansion, infrastructure construction and industrial production usually grow synchronously, leading to an increase in demand for caustic soda and PVC at the same time. Even if the price of PVC rises and drives chlor-alkali enterprises to increase production, if the demand for caustic soda is also growing, the price of caustic soda may not significantly decrease, but may remain at a high level or even rise. In this case, the prices of caustic soda and PVC may rise synchronously rather than offsetting each other.

Figure:The prive of caustic soda and PVC

As an experienced engineering company in the chlor-alkali field (caustic soda field), BPC is committed to providing upgrading services for chlor-alkali clients worldwide.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China